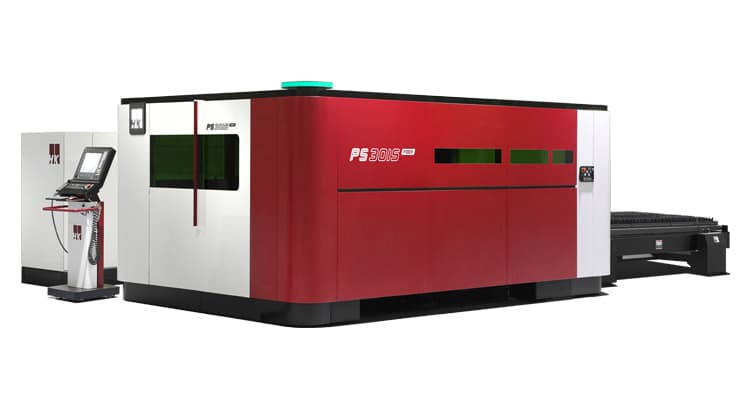

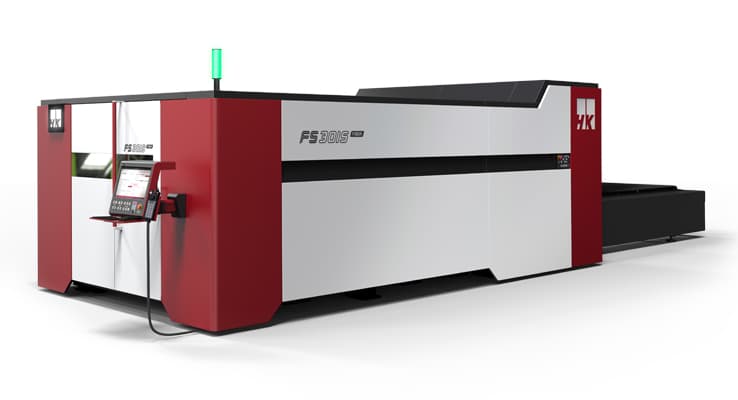

Fiber Laser Machinery Qbh

When it comes to cutting various Fiber laser machines are more efficient at cutting thin metals. A fiber laser machine can cut thin metals efficiently up to 25mm or 1 inch. After that, fiber lasers start cutting metal less efficiently. You would need high amounts of power, which by the way cost a lot more money, to cut ticker metals above 25mm or 1 inch.

However, fiber lasers can be very expensive and you may need a laser engraver that is affordable.